Summary:

- NIT Rourkela’s green concrete beads use sunlight to detoxify industrial wastewater.

- The beads eliminate over 82% of pollutants and are reusable for at least 15 cycles.

- Made from low-cost fly-ash-based concrete, they require no electricity or complex equipment.

- Ideal for small-scale industries and rural communities.

- A dyeing unit outside Rourkela dramatically reduced water costs and pollution using this method.

On a quiet stretch of campus in eastern India, a team of researchers has turned cement, sunlight, and nanoparticles into a weapon against one of India’s most stubborn environmental challenges: toxic wastewater.

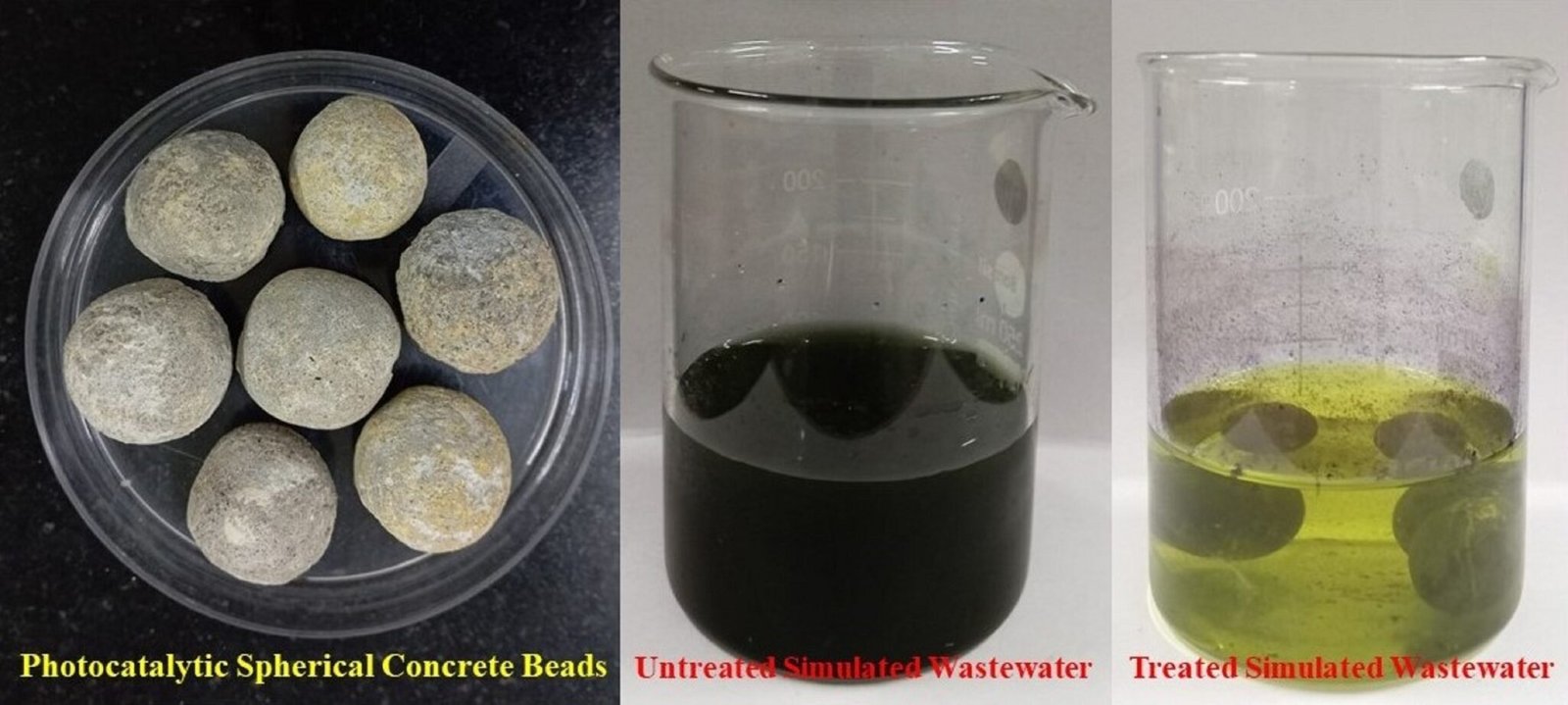

At the National Institute of Technology (NIT) Rourkela, Professor Subhankar Paul and his team have developed small, palm-sized concrete beads infused with graphene oxide and iron-doped nano-titania. When dropped into a tub of polluted water and exposed to sunlight, the beads begin a silent process of breaking down chemical toxins and cleansing the water—no power lines, no filtration units, and no heavy infrastructure required.

“We wanted something that would work in a village, under the sun, with minimal training,” said Prof. Paul. “That was the goal.”

A Simple Bead with Complex Impact

The process is elegant: the beads, made of green concrete using coal fly-ash and cement, are designed to float or sink in water tanks. Sunlight triggers a photocatalytic reaction that breaks down chemical oxygen demand (COD)—a major indicator of water toxicity.

In lab simulations mimicking textile effluent, the beads reduced COD by over 82% in five hours of sunlight. They remained over 90% effective after 15 reuse cycles. Unlike traditional chemical treatment systems, these beads need no electricity, no trained operators, and no imported filters.

“People assume good science must look like a lab. But this science looks like a bowl of pebbles on a rooftop,” said Priya Sahu, a research scholar on the team.

The beads are undergoing field testing and two patents have already been filed—an early sign that this innovation might leave the lab and touch real lives.

The Real Test: A Rural Dyeing Unit Cleans Up

In a small village 20 kilometers from Rourkela, Sunita Mishra, the manager of a modest fabric dyeing unit, remembers the days when murky grey water ran down the drain and local complaints mounted.

“We wanted to be clean,” she said, “but we couldn’t afford the treatment plants.”

Enter the green beads. Provided by the NIT team under pilot testing, the unit began treating its rinse water in large cement tanks placed under the sun.

- COD levels fell by 85%.

- Water could be reused for non-dyeing purposes, saving up to 40% of fresh water needs.

- Monthly expenses on water and pollution control dropped from ₹25,000 to ₹8,000.

Sunita now refers to the beads as “chhoti si aas” — a small hope.

“We don’t just save money now. We save shame,” she added quietly.

Reimagining Clean Water as a Right, Not a Luxury

India produces billions of liters of wastewater daily, much of it untreated. For many small industries and rural municipalities, the infrastructure to clean that water is either too expensive or too complicated.

What NIT Rourkela’s team has done is democratize that solution—bringing it down to size, cost, and skill levels that match real-life conditions.

Their green concrete beads are not just about chemistry. They are about dignity, decentralization, and sunlight—the most abundant resource rural India has.

As the team moves toward scaled deployment, collaborations with Jal Shakti ministries, NGOs, and industrial training boards are being discussed. The vision: every panchayat, school, and factory with its own water-cleaning toolkit—powered by the sun.

In a country where the battle for clean water often feels overwhelming, these concrete beads are small, silent proof that science doesn’t need to be complicated to be revolutionary.